With the continuous development and maturity of 3D printing technology, invisibly has had a positive impact on many industries, like figures, jewelry, dentistry and so on, more and more 3D printing application cases shine in life.

Viewing at Bilibili, people with lofty ideals go farther and farther on the way to create toys for themselves with 3D printing, as if they have walked into a 3D kitchen full of DIY fun.

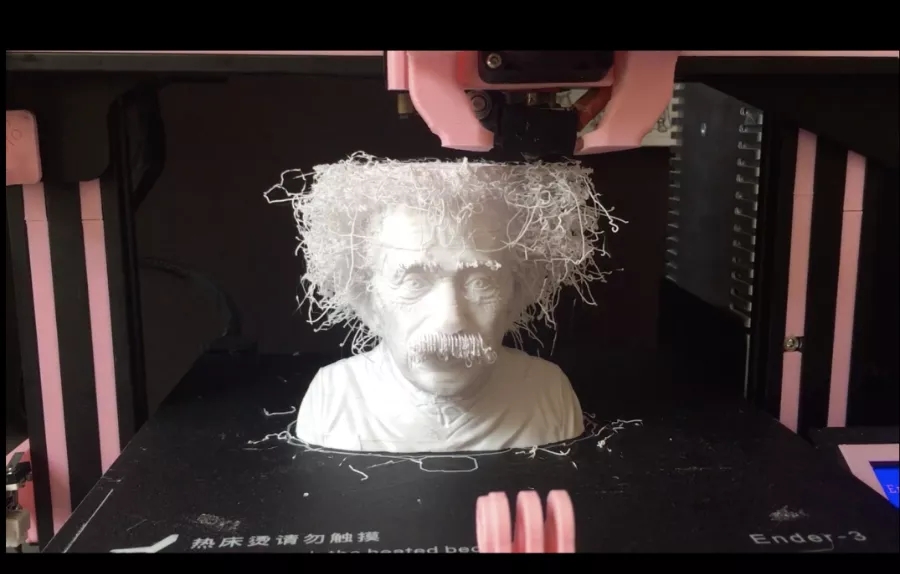

3D printing figure

Einstein

From@Jacob1110

Self-made curvature engine drives the spacecraft (Just kidding)

From@Owen来造

A real Eagle (Just kidding)

From@Troy McMillan

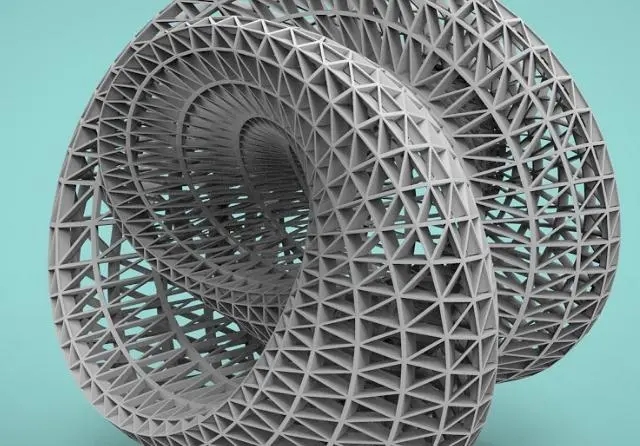

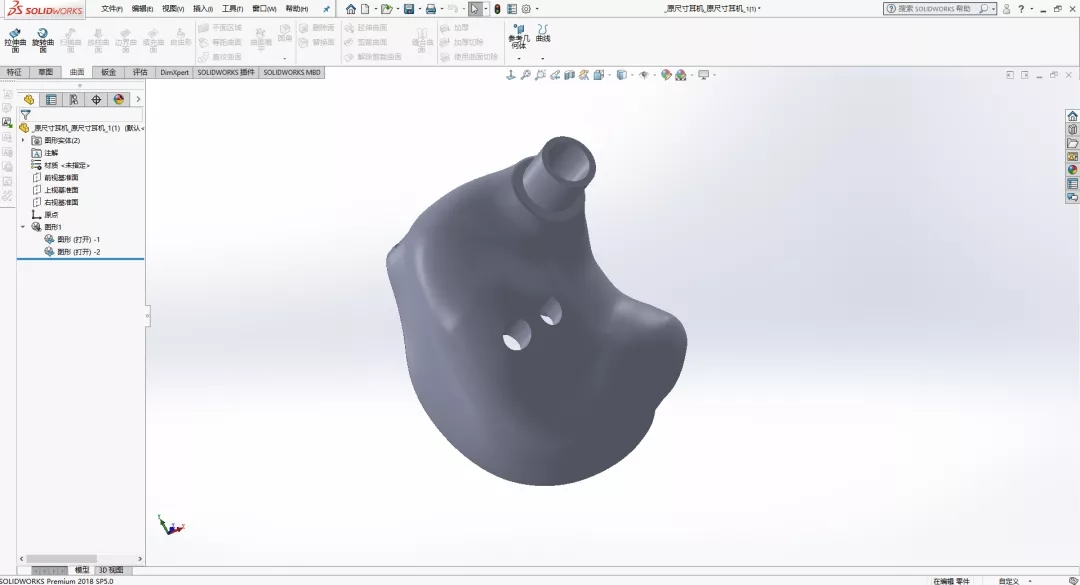

3D printing brings more possibilities to many structures that we could not achieve before, for example, the integrally formed Mobius ring and Klein bottle, to truly feel the changes brought to our lives by 3D printing. Tipsy uses 3D printing technology to customize wireless earphone cavities in batches, through the research of 10,000 private ear model data, the public model cavity designed by comparison has greatly improved the wearing comfort and firmness of the earphone.

Many earphones have been using resin inverted moulding process to make earphone shell, utilizing the curing properties of the photosensitive resin, the earmarks are trimmed, waxed, the agar mold is poured, the shell is cured by the ultraviolet lamp, the uncured resin is poured to clean, and other steps, and the earphone shell is finally obtained.

This method have some disadvantages. First of all, the internal structure of the earphone shell is difficult to achieve complex customized design, which is not conducive to the installation of internal components, and the overall structure design also affects the sound quality.

We use CHITUBOX's powerful and easy-to-use support editing function, and can manually add the most suitable support structure for the unique design of the earphone shell.

Using 3D printing, the internal structure of the earphone shell can be precisely customized, making the installation of components more convenient. At the same time, they can have a higher degree of freedom when designing the sound hole of the earphone. Because the length and thickness of the sound hole have a great influence on the sound quality of the earphone, with 3D printing, any size can be designed. In this way, it is easier to design a headphone structure with better sound quality.